India is one of the world’s largest producers and exporters of peanuts (groundnuts), contributing significantly to the global supply chain. Understanding the peanut harvest season is crucial for international buyers, importers, and commodity traders to plan procurement, manage logistics, and ensure optimal pricing. Here’s a comprehensive look into India’s peanut harvest calendar, production trends, and trade insights.

🗓️ When is the Peanut Harvest Season in India?

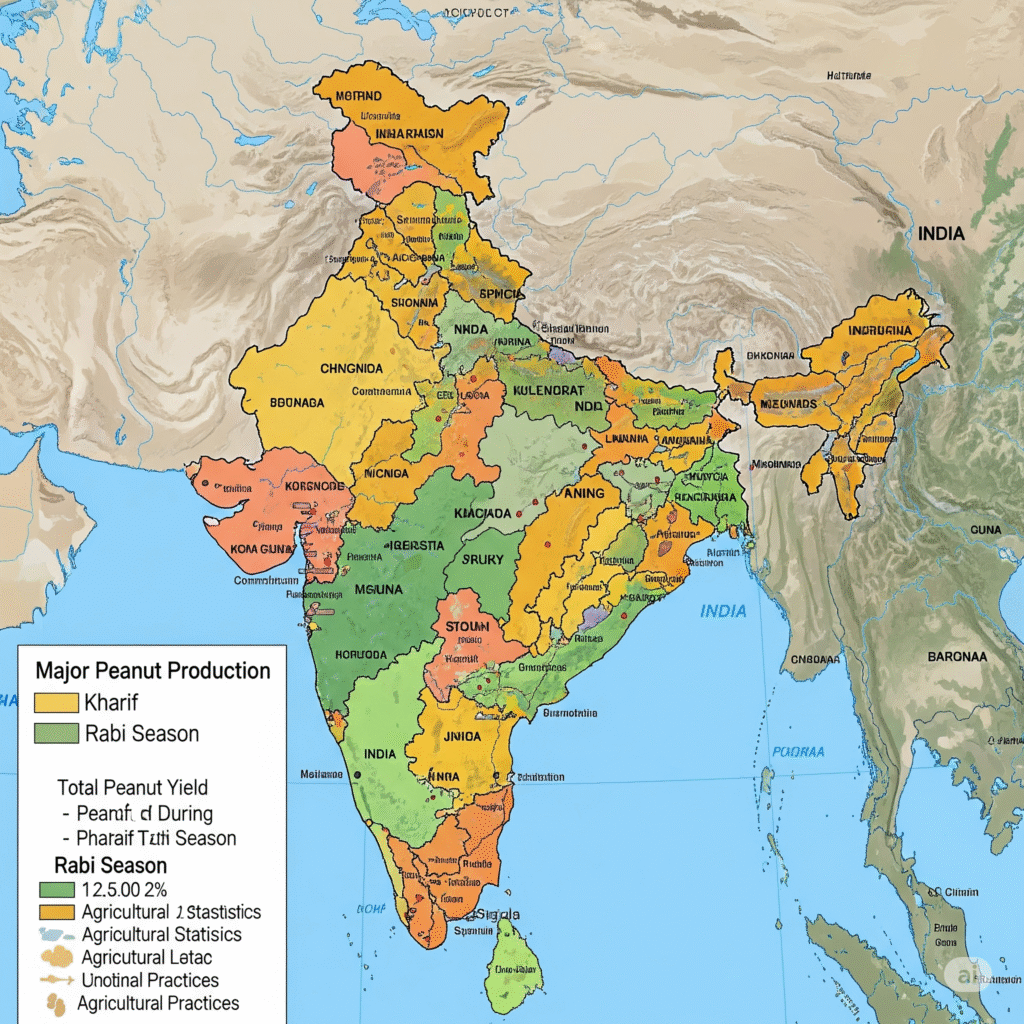

India witnesses two main peanut crops annually, aligned with its climatic seasons:

1. Kharif Season (Monsoon Crop)

- Sowing: June to July

- Harvesting: September to November

- Share in total output: ~70% of total annual peanut production

2. Rabi Season (Winter Crop)

- Sowing: December to January

- Harvesting: March to April

- Share in total output: ~30% of total annual peanut production

These two harvest windows provide a continuous supply chain for both domestic and international markets, allowing buyers to source fresh stocks almost year-round.

📊 Peanut Production: India at a Glance

| Year | Area (Million Hectares) | Production (Million Tonnes) | Major States |

|---|---|---|---|

| 2022–2023 | 5.4 | 10.1 | Gujarat, Rajasthan, Andhra Pradesh, Tamil Nadu, Karnataka |

- Gujarat alone contributes ~35-40% of India’s total peanut output.

- The most common varieties exported include Java, Bold, and TJ (Tandoori Java).

- India’s peanuts are known for their pinkish-white skin, sweet-nutty flavor, and high oil content, making them popular in confectionery, edible oil, and snack industries.

🌍 India’s Global Peanut Export Performance

- India exported over 775,000 MT of peanuts in FY 2023.

- Top importers: Indonesia, Vietnam, Russia, UAE, Iran, and Malaysia.

- India’s peanut exports are regulated under standards set by APEDA, and processed under HACCP, ISO 22000, and USFDA certifications.

🔍 Why Understanding the Harvest Timeline Matters for Buyers

Knowing India’s peanut harvest season allows importers to:

- Plan shipments around fresh harvests to ensure best quality.

- Negotiate pricing based on peak/off-peak supply trends.

- Minimize storage & logistics costs by aligning orders with crop cycles.

- Predict global price shifts, as Indian crop volume directly impacts international peanut prices.

🌦️ Climate Impact on Harvest

India’s peanut crops are highly dependent on monsoon rainfall. A deficit or excess in rainfall during sowing or harvesting seasons can impact:

- Yield quality

- Aflatoxin risk

- Moisture content and shelling ratio

Buyers often secure contracts based on pre-harvest crop estimates to mitigate supply chain disruptions.

✅ Conclusion: Leverage India’s Harvest Calendar to Your Advantage

For importers and international traders, understanding India’s peanut harvest cycles is not just informative—it’s strategic. By aligning procurement strategies with India’s Kharif and Rabi seasons, you can ensure better pricing, superior quality, and consistent supply.

📩 Looking to Source Premium Indian Peanuts?

We offer export-ready Java, Bold, and TJ varieties—processed in certified facilities, aflatoxin-controlled, and customized for international packing needs.

Free consultation on your peanut sourcing needs” or “Get a personalized quote for bulk Indian peanuts.

📧 Email: info@shreeshubhamexim.com

🌐 Website: www.shreeshubhamexim.com

📞 Call/WhatsApp: +91-9170007077